- Home »

- Technology »

- News »

- Actuator robot

Actuator robot

An actuator robot uses actuators to move and do jobs. This is like how muscles help people walk or lift things. Actuators change energy into movement. This lets robots push, pull, or turn parts very accurately. New actuator technology, like electric and hybrid types, makes robots work better and last longer.

|

Aspect |

Robotics Industry Growth |

|---|---|

|

Technological Advancements |

Electric and hybrid actuators save more energy and help the planet. |

|

Material Innovation |

Light and strong materials help robots work well in hard places. |

|

Integration with AI & IoT |

Smarter actuators help robots be more exact and do harder jobs. |

Learning about these changes helps people know why actuator robots are important in many jobs today.

Key Takeaways

-

Actuators turn energy into movement. This lets robots push, pull, or turn parts with control and accuracy.

-

There are different actuator types. These include electric, hydraulic, and pneumatic actuators. Each type fits different jobs. The choice depends on how much force, speed, or accuracy is needed.

-

Smart actuators have sensors. These sensors help robots stay safe and flexible. They change how robots move by using feedback.

-

Picking the right actuator is important. It depends on what the robot does, where it works, and its power source. This helps the robot work better and last longer.

-

New actuator technologies are being made. Some are soft or inspired by nature. These help robots work safely near people and use less energy.

Actuator Robot Basics

What Is an Actuator?

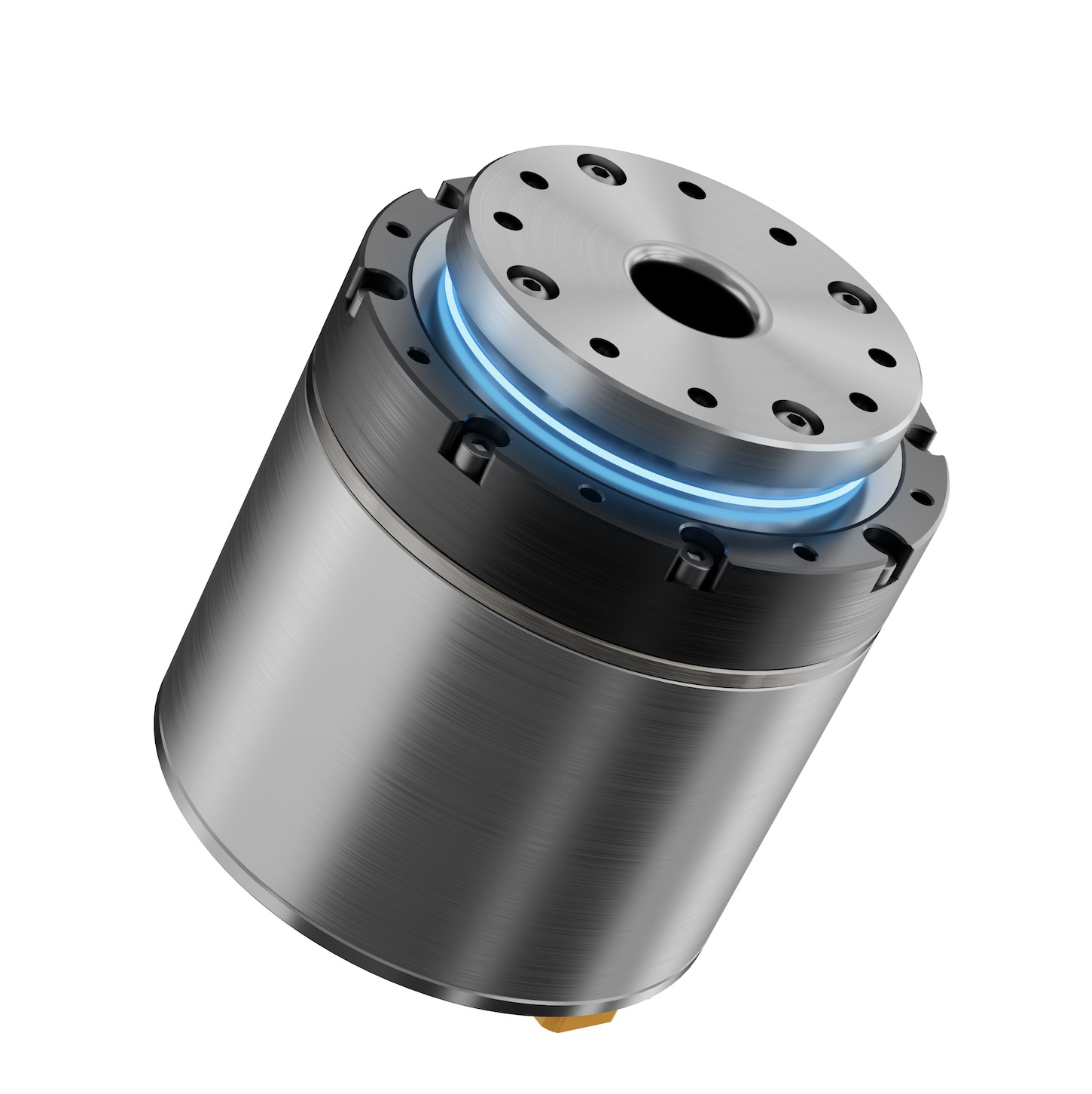

An actuator is a machine part that makes things move or turn. It does this when it gets energy. In robotics, engineers call it a transducer because it changes signals into movement. This happens in a controlled way. Every actuator needs a control device and an energy source. The control signal is usually weak, like a small voltage or a little air pressure. Actuators help robots move themselves and other things. They use energy to turn stored power into work, like a motor does. This work lets the actuator robot lift, push, or turn parts.

How Actuators Work

Actuators change different kinds of energy into motion. The main energy sources are:

-

Electric actuators use electrical energy from DC or servo motors. They turn electric current into movement with electromagnetic forces.

-

Hydraulic actuators use pressurized fluid to make strong force. These are good for heavy robots.

-

Pneumatic actuators use compressed air for fast, light moves. Many automation systems use these.

-

New types, like piezoelectric and shape memory alloy actuators, use electric fields or heat to move.

Actuators work by following Newton’s second law: force equals mass times acceleration (F = m · a). The actuator pushes or pulls a load to make it move. Sometimes, actuators connect to parts like ball screws or gears to change how things move. For example, a linear actuator can make something spin by using a special part. In an actuator robot, the actuator type depends on the job. Some robots need quick, light moves. Others need strong, steady force.

Tip: The kind of actuator and its energy source decide how the actuator robot moves and what jobs it can do.

Why Actuators Matter

Actuators are very important in every actuator robot. They let robots move with care and repeat actions smoothly. This matters for jobs like picking up things, putting parts together, or even doing surgery. Different actuators let robots work in many places. For example, electric actuators give high accuracy and easy control. Hydraulic actuators give strong force for lifting heavy things.

Actuators also help robots work safely. They control speed and force, so movements are not sudden. This keeps people safe near robots. Energy-saving actuators use less power and cost less, so robots last longer. When engineers add smart controls or AI, actuators can change for new jobs. This makes the actuator robot more useful and able to do more.

|

Benefit |

How Actuators Help Robots |

|---|---|

|

Precision |

Smooth, accurate movements |

|

Efficiency |

Fast, reliable operation |

|

Flexibility |

Suits many tasks and industries |

|

Safety |

Reduces abrupt motions |

|

Energy Savings |

Lowers power use and costs |

|

Adaptability |

Adjusts to new tasks with AI |

The right actuator helps a robot do its job well in a factory, hospital, or lab. As actuator technology gets better, actuator robots become even more important in our lives.

Types of Actuators

Electric

Electric actuators use motors to make things move. These motors can be DC, stepper, or servo types. Electric actuators help robots move with great accuracy. They can do the same job over and over. They are quiet and do not make a mess. This makes them good for labs and factories. Electric actuators only use power when moving. This helps save energy. Some electric actuators, like the DYNAMIXEL series, have smart features. These can tell you their position, speed, and temperature.

Note: Electric actuators are simple to program and fit in tight spaces. They may cost more at first and can get hot if used too long.

|

Aspect |

Advantages |

Disadvantages |

|---|---|---|

|

Precision |

Very accurate and can repeat actions |

Needs expert setup |

|

Energy Use |

Only uses power when moving |

Costs more at the start |

|

Maintenance |

Easy to care for, no fluids needed |

Not strong enough for heavy loads |

|

Environment |

Quiet and clean |

Can get too hot with heavy use |

Hydraulic

Hydraulic actuators use oil under pressure to move parts. These actuators can lift or push very heavy things. They work well in big machines and construction robots. Hydraulic actuators give strong and steady force. They use oil that does not squeeze, so movement is easy to control. But hydraulic systems need regular care and can leak oil. Leaks can be unsafe or bad for the environment.

-

Hydraulic actuators are best for jobs that need a lot of power, like lifting heavy things or moving big robot arms.

-

They work at high pressures, sometimes over 10,000 psi, to give strong force.

Pneumatic

Pneumatic actuators use air under pressure to make things move. These actuators move parts fast and are used in pick-and-place robots. Pneumatic systems are safe and clean. They do not give as much force as hydraulic ones. They usually work at pressures between 60 and 120 psi. Pneumatic actuators are good for light jobs. They help robots move quickly and smoothly.

|

Pressure Range (psi) |

Typical Use |

Force Level |

|---|---|---|

|

60 - 80 |

Light pick-and-place tasks |

Lower force |

|

100 - 120 |

Heavy-duty machinery |

Higher force |

Tip: Keeping the right air pressure helps pneumatic actuators last longer and work safely.

Linear and Rotational

Actuators can move in straight lines or spin around. Linear actuators push or pull things, like lifting a robot arm up and down. Rotational actuators turn parts, like spinning a wheel or turning a joint. Both types can use electric, hydraulic, or pneumatic power. Linear actuators are good for jobs that need straight moves. Rotational actuators are best for turning or spinning.

|

Feature |

Linear Actuators |

Rotary Actuators |

|---|---|---|

|

Motion Path |

Moves in a straight line |

Spins in a circle |

|

Applications |

Lifting, pushing, pulling |

Turning, spinning, twisting |

|

Precision |

Very good for straight moves |

Good for spinning |

Smart Actuators

Smart actuators have sensors and controls built in. These actuators can sense their own position, force, and temperature. They change how they move based on feedback. This makes the actuator robot safer and more flexible. Smart actuators often use soft materials. This lets them bend or stretch. It makes them safer to use near people. Real examples are the DYNAMIXEL and T-Series Actuator®. These actuators can use advanced control modes. You can connect many together for complex robots.

Smart actuators help robots learn new jobs and work in new places. They are important for the future of robotics, where safety and flexibility matter most.

Actuator Robot Applications

Industrial

Factories use actuator robots to build cars and electronics. They also weld metal parts. Most industrial robots use electric actuators. These actuators give high accuracy and speed. They also save energy. Car factories use many of these robots. More robots will be used by 2025. Electric actuators help robots weld and check parts very well. They work in tough places for many hours. Pneumatic actuators make robots fast for jobs like picking up things. When engineers add sensors, robots can change how they move right away. This helps them make fewer mistakes and work better.

Actuators let industrial robots move with exact control. This makes robots more reliable and helps people make fewer mistakes.

Healthcare

Hospitals use actuator robots for surgery and patient care. They also help with rehab. DC motors move robots and wheelchairs. Servos turn robot arms for surgery. Stepper motors help medical devices move just right. Linear actuators move beds and lifts for patients. Soft actuators are made from bendy materials. They help robots do gentle jobs like therapy or prosthetics. These soft actuators can bend and stretch. This makes them safe to use near people. Healthcare robots need actuators that move gently and accurately. This keeps patients safe and comfortable.

-

DC motors: Move robots and wheelchairs

-

Servos: Turn robot arms for surgery

-

Stepper motors: Move medical devices with care

-

Linear actuators: Move beds and lifts

-

Soft actuators: Used in wearable devices and prosthetics

Service Robots

Service robots clean, deliver things, and help customers. Actuators act like muscles for these robots. They turn commands into movement. Electric motors move wheels and joints. Soft actuators and fake muscles help robots hold things gently. Smart actuators with sensors and AI help robots move around and handle things carefully. This lets robots work safely in homes, hotels, and hospitals.

-

Actuators help robots move, pick up things, and talk to people.

-

Sensors and actuators work together so robots can change how they act.

Research and Innovation

Researchers use actuator robots to try new ideas. They also make better machines. Some new actuators act like human muscles. They can change how stiff they are. This makes robots safer and more flexible. New materials like shape-memory alloys and special polymers make actuators work better. 3D printing helps make complex actuators with sensors inside. These new things help robots do careful jobs, like surgery or working with breakable things, with great accuracy.

|

Innovation |

Description |

Benefit |

|---|---|---|

|

Artificial muscles |

Act like real muscles |

Flexible, strong, and safe moves |

|

Nano-actuators |

Work at a tiny size |

Help tiny robots and fine control |

|

Sensorized actuators |

Have sensors and actuators together |

Give real-time feedback and accuracy |

|

Artificial skin |

Feels touch and pressure |

Helps robots interact better |

Selection and Trends

Choosing Actuators

Picking the best actuator for a robot is important. Engineers first decide what kind of movement the robot needs. It could be straight, spinning, or back-and-forth. They check how much force or turning power is needed. They also look at how fast the actuator should move. The job might need the actuator to move a certain distance. Some jobs need very careful and exact moves. The energy source, like electricity or air, must be safe and easy to get. The actuator must fit inside the robot’s space. Hot, cold, or wet places can change which actuator works best. Engineers want actuators that last long and are easy to fix.

-

Type of motion: linear, rotary, or oscillatory

-

Force and speed requirements

-

Precision and accuracy needs

-

Energy input and availability

-

Space and design limits

-

Environmental conditions (temperature, dust, moisture)

-

Maintenance and reliability

Tip: Choosing the right actuator for the job helps robots work better, safer, and longer.

Performance Factors

Force, speed, and precision all affect how actuators work. If an actuator needs to push hard, it might move slower. Fast actuators are good for quick jobs. Slow actuators help with careful work. Precision is very important for building things or surgery. Sensors and feedback help actuators move to the right spot every time. Engineers also think about friction, wearing out, and noise. The place where the robot works can change how well actuators do their job. Very hot, cold, or dusty places may need special parts.

|

Factor |

Why It Matters |

|---|---|

|

Force |

Moves heavy or light loads |

|

Speed |

Controls how fast parts move |

|

Precision |

Ensures accurate, repeatable actions |

|

Durability |

Handles wear and tough conditions |

|

Energy Use |

Saves power and lowers costs |

Future Trends

Actuator technology is always getting better. Soft actuators can bend and stretch because they use flexible stuff. These are good for robots that work near people. Some actuators are made to act like muscles and tendons. This helps robots move more like people. Saving energy is very important now. New motors and smart materials use less power. Some actuators can even get energy from their surroundings. Smarter controls help actuators learn and change for new jobs. The actuator market is growing fast because of new ideas and materials.

|

Trend Type |

Description |

Key Benefits |

|---|---|---|

|

Soft Robotics |

Flexible actuators for safe, gentle movement |

Safety, versatility |

|

Bio-Inspired Designs |

Mimic muscles and tendons for natural motion |

Efficiency, adaptability |

|

Energy Efficiency |

Use of smart materials and control for less power use |

Lower costs, longer operation |

Actuators decide how robots move and do their jobs. They also help robots learn new tasks. Picking the best actuator depends on how exact, strong, or fast it needs to be. Here is a table that shows the differences:

|

Actuator Type |

Precision Level |

Force/Torque |

Speed Capability |

|---|---|---|---|

|

Electric |

High |

Medium |

Medium |

|

Hydraulic |

Medium |

High |

Low |

|

Pneumatic |

Low |

Medium |

High |

Engineers also think about where the robot will work. They check how easy it is to fix and control the actuator. Learning about new actuator technology helps teams make robots safer and smarter. It also helps robots work better and last longer.

FAQ

What does an actuator do in a robot?

An actuator makes a robot move. It changes energy into motion. The robot can lift, push, pull, or turn parts. Actuators help robots do jobs in factories, hospitals, and homes.

How do engineers pick the right actuator?

Engineers look at the job the robot must do. They check force, speed, and accuracy needs. They also think about size, power, and where the robot will work. The right actuator helps the robot work well.

Can actuators make robots safer?

Yes. Smart actuators use sensors to control speed and force. They help robots move smoothly and stop quickly if needed. This keeps people and machines safe.

What is a smart actuator?

A smart actuator has built-in sensors and controls. It can sense its position, force, or temperature. The robot can change how it moves based on feedback. Smart actuators help robots learn new tasks.

Where do people see actuator robots in daily life?

People see actuator robots in car factories, hospitals, and even homes. Service robots clean floors. Medical robots help doctors. Factory robots build products. Actuators make all these robots move and work.