You are here:

Robotics components

Views: 1597

Author: Site Editor

Publish Time: 2025-06-19

Origin: Site

Robotics components give robots the ability to sense, move, and process information. Key parts include sensors, actuators, control systems, power supply, chassis, software, user interface, and communication interfaces. Each part serves a unique purpose. Sensors collect data from the environment. Actuators produce movement. Control systems manage actions. Power supplies provide energy. The chassis supports the structure. Software drives logic. User interfaces allow people to interact. Communication interfaces link robots to other devices.

| Metric | Description | Example Values / Notes |

| Robotic Tending Efficiency | Efficiency of robotic machine tending compared to manual tending | Robotic: ~90%, Manual: 40%-60% |

| Overall Equipment Effectiveness (OEE) | Composite metric combining availability, performance, and quality to evaluate production efficiency | OEE = Availability × Performance × Quality |

| Availability | Ratio of actual working time without failures to scheduled time | (Available work time - failure time) / scheduled time |

| Performance | Ratio of ideal cycle time to real cycle time or real products to ideal products | Ideal cycle time / Real cycle time |

| Quality | Ratio of good quality products to total products | Number of good products / Total products |

Key Takeaways

- Robotics components like sensors, actuators, control systems, power supply, and chassis work together to help robots sense, move, and make decisions.

- Sensors collect important data from the environment, enabling robots to detect light, distance, force, and more for precise actions.

- Actuators convert energy into movement, allowing robots to lift, move, and perform tasks with strength and accuracy.

- Control systems act as the robot’s brain, processing information and sending commands to ensure fast and accurate responses.

- Good communication systems, both wired and wireless, help robots share data quickly and reliably, supporting different tasks and environments.

Robotics components

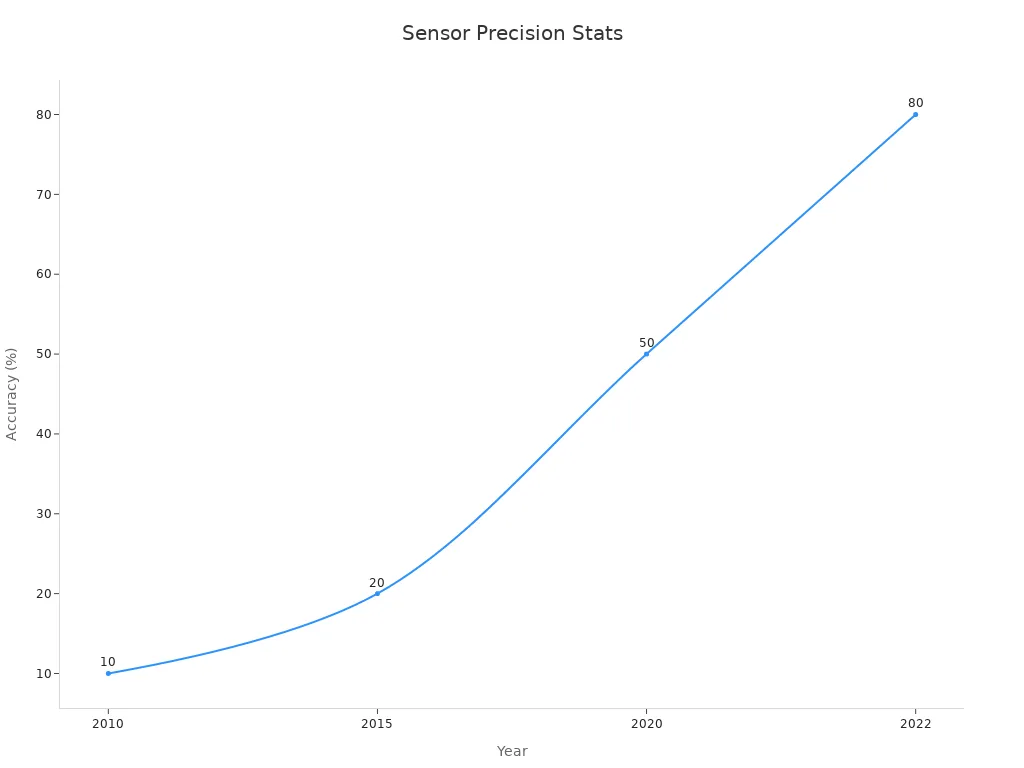

Sensors

Sensors act as the eyes and ears of a robot. They collect information from the environment, allowing robots to detect light, sound, distance, temperature, force, and more. Modern robotics components rely on sensors for precise and reliable operation. For example, light sensors help robots follow lines, while ultrasonic sensors measure distance to avoid obstacles. Tactile sensors allow robots to feel pressure or touch.Recent advances have greatly improved sensor precision. The table below shows how force sensing accuracy has increased over the years:

| Year | Force Sensing Accuracy (%) |

| 2010 | 10 |

| 2015 | 20 |

| 2020 | 50 |

| 2022 | 80 |

Sensors now enable robots to detect subtle force changes and handle delicate tasks. For instance, the Multi-layered Vision-Based Tactile Sensor (ML-VBTS) achieves about 60% better sensitivity than previous models. This improvement helps robots perform complex manipulations with greater care and accuracy.

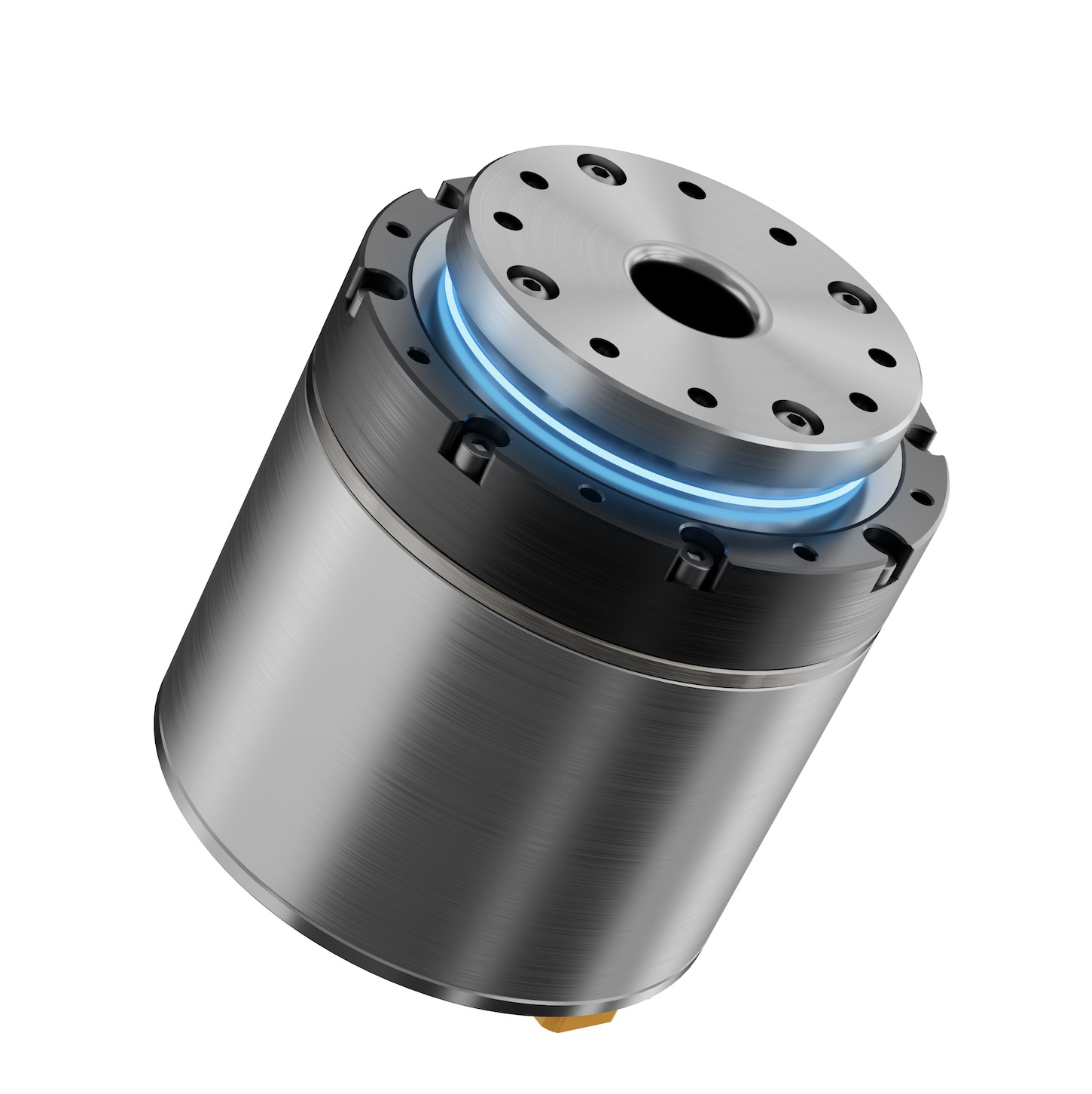

Actuators

Actuators serve as the muscles of robotics components. They convert electrical signals into movement. Common types include electric motors , hydraulic cylinders, and pneumatic actuators. These devices allow robots to move arms, wheels, or grippers.Engineers measure actuator performance using several metrics:

- Maximum torque: Shows how much force the actuator can produce.

- Torque-to-mass ratio: Indicates power density, important for mobile robots.

- Efficiency: Measures how well the actuator converts energy into motion.

- Range of motion: Describes how far the actuator can move.

Control system

The control system acts as the brain of robotics components. It processes sensor data and sends commands to actuators. Most robots use microcontrollers or CPUs for this purpose. The control system ensures the robot follows instructions and adapts to changes in its environment.Key benchmarks for control systems include:

| Benchmark Metric | Description | Importance in Robotics Control Systems |

| Latency | Time delay between input and output | Critical for real-time control and fast reaction |

| Response Time | Time taken to respond to a stimulus | Essential for quick adjustments |

| Throughput | Data processed per time frame | Important for handling large sensor data |

| Processing Capacity | Computational resources available | Supports complex calculations |

| Accuracy | Output matches desired result | Vital for precise control |

| Precision | Consistency of output | Ensures repeatability and reliability |

Power supply

The power supply provides energy to all robotics components. Batteries, such as lithium-ion packs, are common in mobile robots. Some robots use direct electrical connections or fuel cells.Efficient power supplies offer several benefits:

- Lower energy costs and less heat generation.

- Smaller and lighter designs, which are important for mobile robots.

- Improved safety, especially with 48 V systems that reduce current draw and heat loss.

- Fast startup times, which boost productivity.

Chassis

The chassis forms the skeleton of a robot. It supports all other robotics components and protects them from damage. Engineers design chassis using materials like steel, aluminum, or advanced plastics.Studies show that flexible chassis designs absorb impacts better than rigid ones. For example, a flexible chassis can recover its shape after a collision, while a rigid one may crack or deform. Real-world tests include driving robots over rough terrain or even under a car to check durability.

| Parameter | Details / Values |

| Material studied | AISI 4130 steel (Chrome-moly) |

| Tensile Strength | 731 MPa |

| Yield Strength | 460 MPa |

| Bending Strength | 477 Nm |

| Bending Stiffness | 4258 Nm² |

| Application | Roll cage and tubular space frame chassis design |

Strong and durable chassis materials, such as AISI 4130 steel, help robots survive tough conditions and heavy loads. This strength is crucial for industrial robots and those used in outdoor environments.

Robotics components work together to create machines that sense, move, and interact with the world. Each part, from sensors to chassis, plays a vital role in the robot’s performance and reliability.

Software and interface

Software

Software gives robots the ability to think, plan, and make decisions. It controls how the robot uses its sensors and actuators. Programmers write code that tells the robot what to do in different situations. Some robots use simple programs for basic tasks, while others use advanced software for learning and adapting.Robotic software often includes:

- Operating systems that manage hardware and resources.

- Algorithms for navigation, object recognition, and decision-making.

- Communication protocols for sharing data with other devices.

Well-designed software improves a robot’s performance and helps it handle new or unexpected events.

User interface

The user interface (UI) lets people interact with robots. A good UI makes it easy to give commands, receive feedback, and understand what the robot is doing. Designers use many types of interfaces, such as touchscreens, buttons, voice commands, and even gestures.User experience (UX) research shows several important findings:

- UX evaluation in social robotics focuses on user feelings and interaction design.

- Common methods include questionnaires, interviews, and surveys.

- The ANEMONE framework helps assess how well humans and robots understand each other.

- Early feedback from users helps developers improve robot interfaces.

- Key design factors include safety, context, physical design, and interaction style.

- Combining different evaluation methods gives better results.

A well-designed user interface increases trust and makes robots more helpful in daily life.

Communication systems

Robots need to share information quickly and reliably. Communication systems connect different parts of a robot or link several robots together. These systems use either wired or wireless methods. Each method has strengths and weaknesses that affect how robots perform in real-world tasks.Wired communication

Wired communication uses cables to send data between robot components. Engineers often choose Ethernet cables for industrial robots. Wired systems offer high speed and stable connections. They work well in places where robots stay in one area.| Performance Metric | Wired Communication | Wireless Communication |

| Speed | 100–1000 Mbps | 50–600 Mbps |

| Stability (Variation) | 5% | 20% |

| Latency | 1–5 ms | 10–30 ms |

| Interference | Minimal | Prone to interference |

| Security | Higher (less susceptible) | Lower (more vulnerable) |

Wired communication remains the top choice for robots that require real-time data and high reliability.

Wireless communication

Wireless communication lets robots move freely without cables. Technologies like Wi-Fi, Bluetooth, and XBee modules allow robots to send and receive data over the air. Wireless systems support mobile robots and teams of robots working together.Researchers have improved wireless reliability by using special antennas and smart control systems. For example, XBee 900 MHz modules show message delays between 10 and 20 milliseconds, with very little jitter, even at distances up to 12 meters. Robots can also form mesh networks, which help them cover large areas and keep connections strong.

| Research Focus | Key Findings | Impact on Robotics |

| Active antenna tracking | Boosts wireless range and quality | Useful for rescue and surveillance robots |

| Mesh networks | Robots reduce hop counts | Increases network speed and coverage |

| Smart control switching | Local control during signal loss | Keeps robots stable and safe |

Wireless communication gives robots the freedom to move and work in changing environments, but it needs smart design to handle delays and keep data flowing smoothly.

Advanced parts

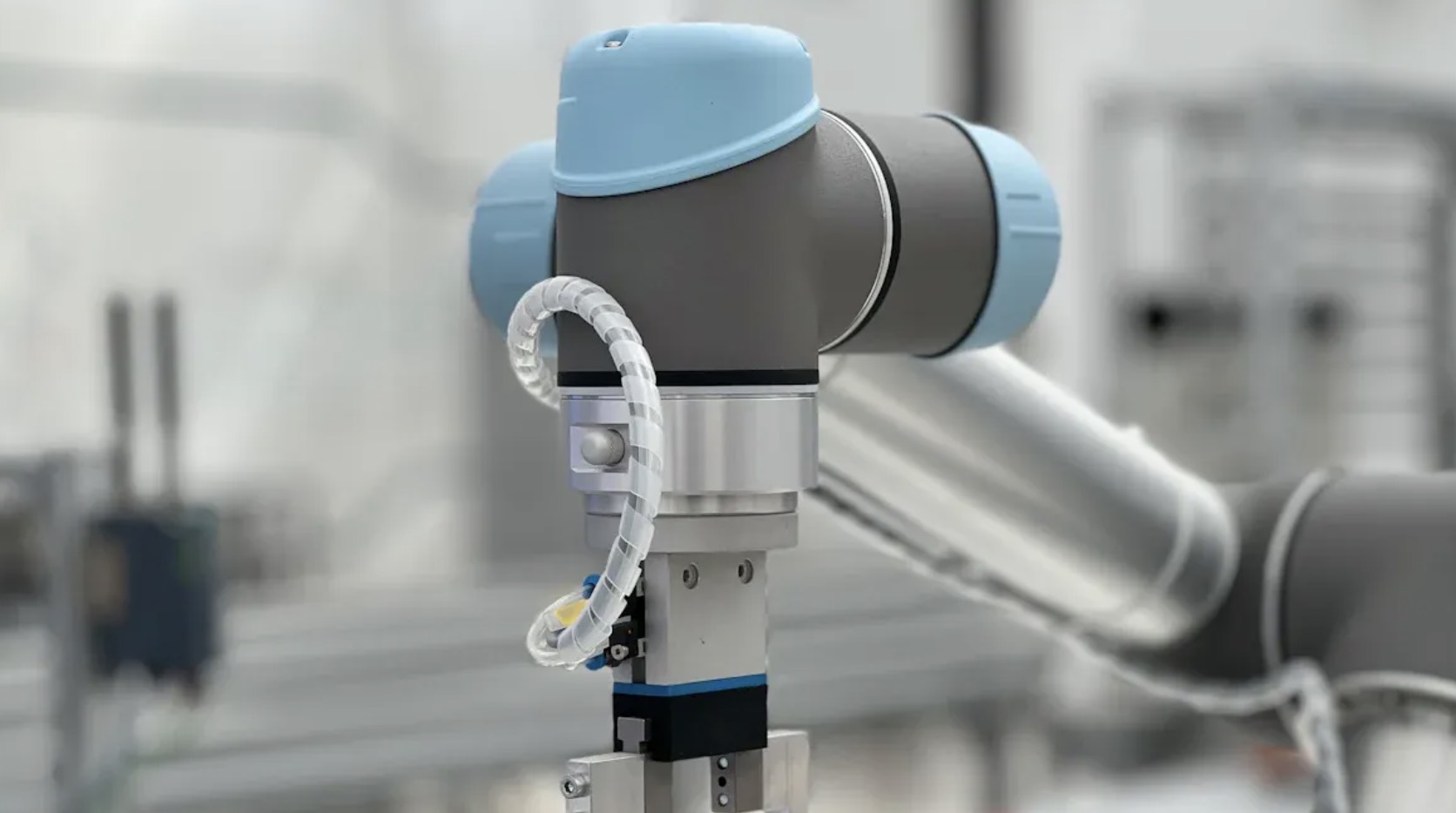

End effectors

End effectors are the tools at the end of a robot arm. They help robots grip, weld, cut, or perform other tasks. Engineers design end effectors for specific jobs, such as picking up small parts or handling delicate objects. In factories, robots with special end effectors can assemble products quickly and safely. In hospitals, surgical robots use advanced end effectors for precise operations. The use of specialized end effectors has grown in many fields.| Sector/Region | Statistic Description | Percentage/Value |

| Manufacturing | Increase in robotic arms equipped with specialized end effectors | 20% increase (McKinsey 2023) |

| Healthcare | Annual increase in surgical robots using advanced end effectors | 18% increase (WHO 2023) |

| Asia-Pacific Region | Annual growth in robotics adoption including end effectors | 20% growth (APEC 2023) |

| Japan | Increase in robotic system installations including end effectors | 25% increase (JARA 2023) |

| Global Market Size | Robot end effector market value in 2024 | USD 2.4 billion |

| Market Projection | Expected market value by 2031 with CAGR | USD 8.39 billion, CAGR 16.95% |

End effectors make robots more useful in manufacturing, healthcare, and education by allowing them to perform many different tasks.

Feedback devices

Feedback devices help robots know their exact position and movement. These devices include sensors that measure distance, force, and angle. When a robot arm moves, feedback devices send data to the control system. This information helps the robot adjust its actions in real time. Engineers use tests that track a robot’s position and orientation to check accuracy. Kinematic calibration with feedback devices, such as laser trackers, can improve a robot’s positioning accuracy to about 0.10–0.30 mm. Studies show that feedback-based calibration reduces errors from several millimeters to less than half a millimeter. This improvement helps robots work with greater precision in factories, labs, and underwater environments.Manipulators

Manipulators are robotic arms or limbs that move and control end effectors. They give robots the ability to reach, lift, and interact with objects. Manipulators can have many joints, which allow them to move in different directions. Performance studies show that manipulators help robots work with people and handle complex tasks. For example, a 7-degree-of-freedom manipulator can move its end effector in all directions and apply force as needed. Mobile manipulators combine arms with moving bases, so robots can travel and work in large spaces. These features make manipulators important in industrial, educational, and marine robotics. They increase the range and versatility of robotics components, allowing robots to do more jobs in more places.Advanced robotics components, such as end effectors, feedback devices, and manipulators, work together to create robots that are precise, flexible, and safe for many industries.

Summary table

Component overview

Robotics components work together to help robots perform tasks with precision and reliability. Engineers use several key metrics to compare these parts. These metrics include accuracy, repeatability, speed, and payload capacity. Each metric helps show how well a robot can complete its job in different environments. Testing often takes place at maximum speed and with heavy loads to check if the robot stays accurate and consistent. Engineers use special tools like laser trackers and 3D measurement systems to collect data. They also use statistical methods to make sure the results are reliable.A clear summary table helps students and engineers understand how each part affects the robot’s overall performance. This approach follows international standards and supports better robot design.

| Robotics Component | Accuracy | Repeatability | Speed | Payload Capacity | Thermal Compensation | Task-Specific Performance | Measurement Methods | Statistical Reliability |

| Sensors | High (detects small changes) | Very high | Fast response | N/A | Stable in most conditions | Detects light, sound, force | Camera, laser, 3D sensors | Data checked for consistency |

| Actuators | Precise movement | Returns to same position | High velocity | Lifts heavy loads | May need cooling | Lifting, rotating, gripping | Torque sensors, encoders | Tested at different speeds |

| Control System | Accurate commands | Consistent output | Fast processing | Handles many tasks | Adjusts for heat | Navigation, decision-making | CPUs, microcontrollers | Analyzed for errors |

| Power Supply | Stable voltage | Reliable output | Quick recharge | Supports robot weight | Manages heat well | Long operation time | Battery testers | Monitored over cycles |

| Chassis | Holds shape | Withstands stress | Supports movement | Carries all parts | Resists bending | Survives impacts | Strength tests | Checked after impacts |

Robotics components must work together for a robot to perform tasks safely and efficiently. Each part—sensors, actuators, control systems, power supply, and chassis—plays a unique role. Companies like Zymergen and Steven Douglas Corp. have shown that well-integrated robotics components lead to higher efficiency and better results.

Key performance metrics include accuracy, safety, and how well the robot matches human intent.

| Component | Key Metric Example |

| Perception | Sensor accuracy |

| Action Execution | Task success rate |

| Safety | Collision avoidance |

FAQ

What is the most important component in a robot?

Every robot needs all its main parts to work well. Sensors, actuators, control systems, power supply, and chassis each play a key role. The most important part depends on the robot’s job.Tip: Engineers always match components to the robot’s purpose.

How do sensors help robots?

Sensors let robots collect information about their surroundings. They can detect light, sound, distance, or touch. This data helps robots make decisions and react to changes.- Example: A robot uses a distance sensor to avoid bumping into walls.

Can robots work without software?

Robots need software to follow instructions and process data. Without software, a robot cannot move, sense, or make choices. Software acts as the robot’s brain.Why do robots use both wired and wireless communication?

Wired communication gives fast and stable data transfer. Wireless communication lets robots move freely. Engineers choose the best method based on the robot’s needs and environment.| Communication Type | Best Use Case |

| Wired | Factory robots |

| Wireless | Mobile or outdoor robots |

What are end effectors used for?

End effectors are tools at the end of a robot arm. They help robots grip, cut, weld, or perform other tasks. Different jobs need different end effectors.Note: End effectors make robots useful in many industries.

×

×