Dual Circular Spline Harmonic Drives: Unveiling Enhanced Torque and Performance in Specialized Gear Systems

Views: 1373

Author: Site Editor

Publish Time: 2025-04-27

Origin: Site

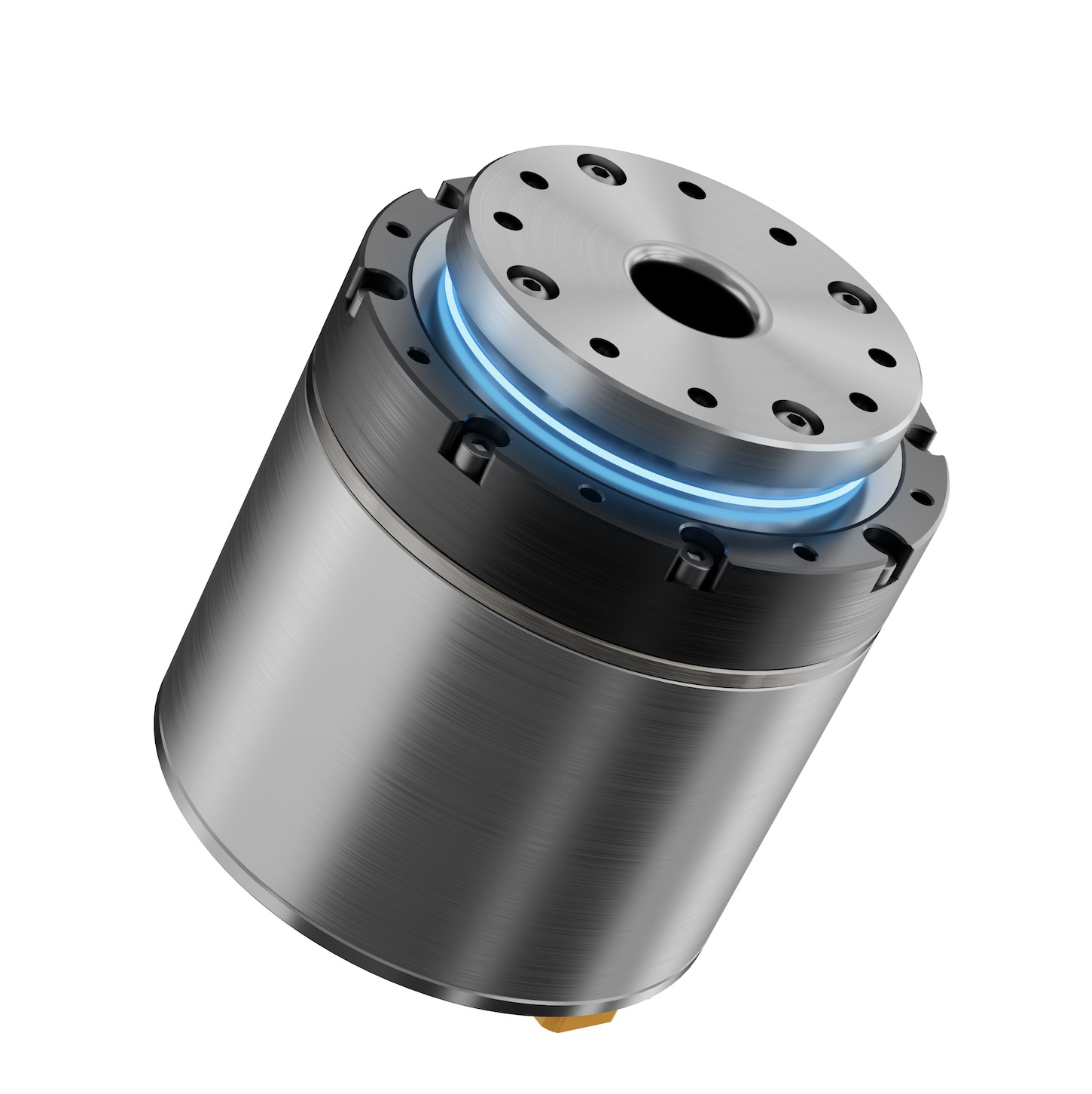

Yes, there are harmonic drive products on the market that incorporate two circular splines, often referred to as dual circular spline designs. This variation builds on the traditional strain wave gear principle but introduces a second circular spline to enhance performance in specific applications. While the classic harmonic drive consists of one wave generator, one flexspline, and one circular spline, the dual circular spline configuration typically aims to improve torque capacity, stiffness, or load distribution.

Other manufacturers, such as Harmonic Drive SE or Cone Drive, may also offer similar configurations under different branding, often marketed as high-torque or heavy-duty strain wave gears. These products are less common than the standard single circular spline design but are available for specialized needs.

How It Works

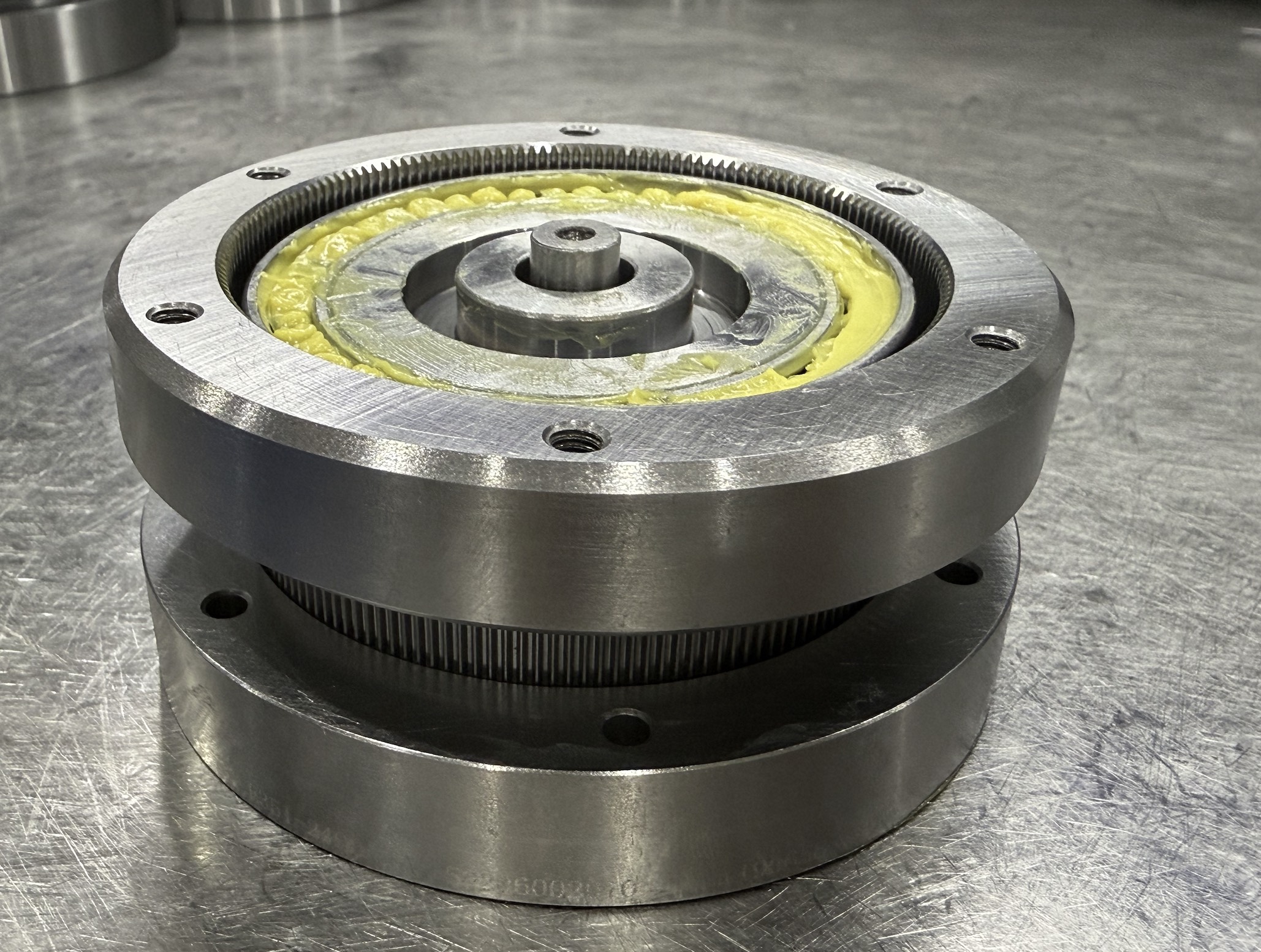

In a harmonic drive with two circular splines:

- The wave generator still deforms the flexspline into an elliptical shape, as in the standard design.

- Instead of engaging with just one rigid circular spline, the flexspline interacts with two circular splines , which are typically positioned concentrically or in a way that they both mesh with the flexspline’s external teeth.

- The two circular splines might have slightly different tooth counts or be arranged to work in tandem, depending on the design. For example, one could be fixed while the other serves as the output, or both could be fixed to split the load.

Real-World Examples

One specific product line that features a dual circular spline design is the FR series from Harmonic Drive LLC. This is a "pancake-style" harmonic drive, which uses a double wave generator bearing and two circular splines to achieve higher torque capacity. The FR series widens the tooth engagement area by incorporating two circular splines, making it suitable for applications requiring robust performance in a compact form factor. The design retains the zero-backlash characteristic of traditional harmonic drives while boosting load-carrying capability.Other manufacturers, such as Harmonic Drive SE or Cone Drive, may also offer similar configurations under different branding, often marketed as high-torque or heavy-duty strain wave gears. These products are less common than the standard single circular spline design but are available for specialized needs.

Advantages

- Increased Torque : More teeth in contact means better torque transmission.

- Improved Stiffness : Dual splines can reduce torsional deflection under load.

- Load Sharing : Distributing forces across two splines can enhance durability.

Trade-offs

- Complexity : Adding a second circular spline increases manufacturing and assembly challenges.

- Cost : These designs are typically more expensive.

- Size : While still compact, they may be slightly larger or heavier than single-spline versions.

×

×