You are here:

Everything You Need to Know About Harmonic Drives

Views: 1956

Author: Site Editor

Publish Time: 2025-06-19

Origin: Site

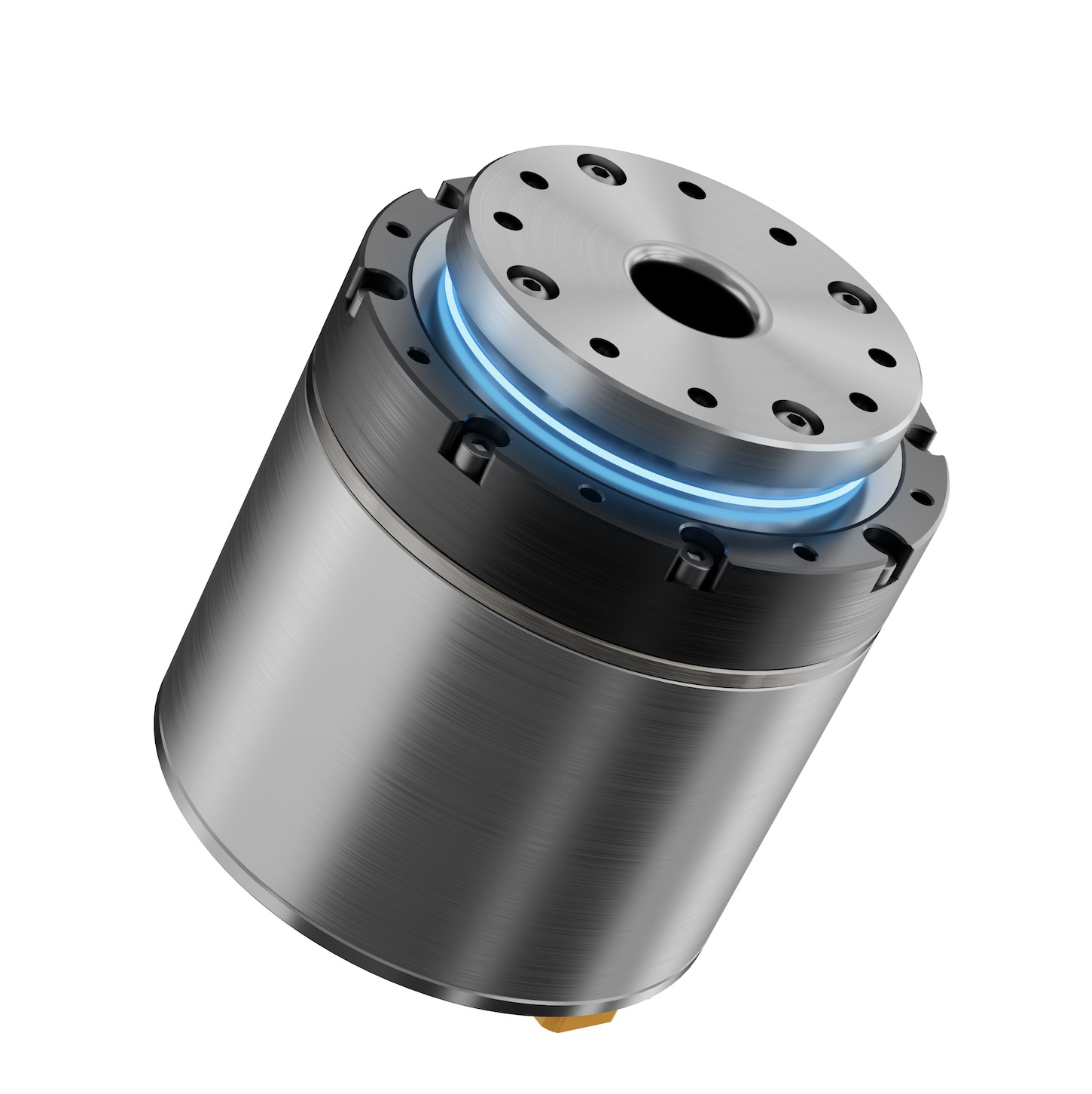

Harmonic drives are special gear systems that use a flexible spline and a wave generator to create smooth, precise motion. Many industries rely on these drives for their ability to deliver high torque and accuracy in a compact design. The robotics, aerospace, and medical sectors all depend on harmonic drives to achieve reliable performance and exact positioning.

Unlike traditional gears, harmonic drives offer zero backlash and can reach reduction ratios up to 500:1 in one stage. This unique design ensures high efficiency, quiet operation, and outstanding positional accuracy.

Research shows that changing the size and shape of these parts can improve how well the system works. For example, using lighter materials like PEEK instead of steel for the rigid wheel can lower weight by 38% and reduce stress on the flex spline by almost 69%. These changes do not reduce how efficiently the system transmits power.

Studies have found that the flex spline faces the most stress at the top of its teeth. Over time, wear between the flex spline and the circular spline can affect how accurately the system moves. Engineers use special materials and shapes to make the flex spline last longer and work better. They also study how the flex spline handles repeated bending and twisting to make sure it stays strong.

Tests using laser sensors show that the wave generator causes both regular and random bending in the flex spline. The amount of bending changes with speed. The flexible bearing inside the wave generator helps control these movements, making the system more reliable.

The deformation mechanism works because the flex spline is stiff when twisted but can bend easily in and out. The teeth on the flex spline and circular spline stay in contact along the major axis of the oval. This contact happens over many teeth at once, not just one or two. The S-tooth profile increases the area where the teeth touch. This spreads out the force and helps the gear last longer.

These measurements help engineers understand how well the deformation mechanism works. High efficiency means less energy is lost as heat. The flex spline’s ability to bend and return to shape allows the gear to work smoothly for a long time.

Tip: The unique deformation mechanism in harmonic drives allows for high reduction ratios and smooth, quiet operation.

Tests show that harmonic drives have almost no backlash. Engineers measure backlash by locking the wave generator and circular spline, then applying torque to the flex spline in both directions. They measure how much the flex spline twists before the teeth move. The results show a very small amount of lost motion, called torsional backlash. Finite element analysis supports these results. Choosing the right size for the flex spline and circular spline is important for keeping backlash low.

Rotational accuracy shows how closely the output matches the input.

Torque transmission capacity tells how much force the gear can handle.

Efficiency measures how much input power turns into useful output.

Lifespan shows how long the gear will last.

Quietness means the gear does not make much noise.

Minimal backlash means the gear moves smoothly and stops exactly where needed.

These features make harmonic drives a top choice for robots, airplanes, medical machines, and other equipment that need precise, reliable motion.

Note: Careful design and testing help harmonic drives reach the high accuracy needed for robotics, aerospace, and medical devices.

Tip: Compact harmonic drives help reduce the overall size and weight of machines, making them easier to transport and maintain.

High torque output with a small size helps robots work in tight spaces.

Low or zero backlash ensures robots stop and start exactly where needed.

High repeatability allows robots to perform the same task over and over.

Compact design makes robots lighter and easier to build.

Robots in industrial automation, healthcare, and collaborative settings benefit from these features. For example, surgical robots use these gears to make tiny, careful movements during operations. Collaborative robots, or cobots, work safely alongside people because of their precise control.

NASA first used these gears in the Apollo 15 lunar rover in 1971. Since then, they have appeared in space telescopes and Mars rovers. The gears offer zero backlash and high reduction ratios, which are important for space equipment. They also use strong materials that can survive cold and work without oil. These features help spacecraft move smoothly and stay reliable during long missions.

Medical imaging equipment also uses these gears to position cameras and tools with great accuracy. The compact size and high precision make them ideal for devices that must fit inside the human body or work in crowded operating rooms.

Note: Ultra-high accuracy gears are growing in demand, especially for aerospace and surgical robots, where even the smallest error can matter.

Drives with high torque-to-weight ratios work well in robots and aerospace systems. Some models reach input speeds up to 7,500 rpm. Engineers compare these numbers with other systems, such as cycloid or planetary gears, to find the best fit.

Tip: Always check the drive’s material and sealing options for the intended environment.

High precision ensures smooth, reliable motion. Engineers select drives that meet or exceed these standards for critical tasks.

A simple inspection checklist helps workers remember each step. They should record any issues and fix them right away.

Note: Good maintenance keeps gear systems reliable and extends their service life.

Traditional gears also need more space because of their design. They often require extra parts to reduce backlash or increase torque. Engineers sometimes add springs or special shapes to improve performance, but these changes can make the system more complex. Maintenance for traditional gears can be higher because of wear on the teeth.

Note: Harmonic drives offer better precision and less backlash than traditional gears. This makes them a better choice for

robots

and medical devices.

Cycloidal gears are usually larger and heavier. Their design uses more moving parts, which can increase noise and vibration. Engineers choose cycloidal gears for heavy-duty jobs, but they may not fit in small spaces. Harmonic drives, with their flexible spline and wave generator, provide smoother motion and higher accuracy.

Note: Improved performance helps machines run longer and need less repair.

| Application Sector | Importance of Harmonic Drives |

| Robotics | Positional accuracy, high torque density, compact size |

| Aerospace | Lightweight, precise positioning, high torque capacity |

| Medical | Precise and reliable motion control |

Key Takeaways

- Harmonic drives provide precise, smooth motion with almost no backlash, making them ideal for robotics, aerospace, and medical devices.

- Their compact design delivers high torque in a small size, saving space and weight without sacrificing strength or accuracy.

- The flexible spline and wave generator work together to create reliable motion by bending without breaking, ensuring long-lasting performance.

- Regular inspection, cleaning, and proper lubrication keep harmonic drives running smoothly and extend their lifespan.

- Compared to traditional and cycloidal gears, harmonic drives offer better precision, quieter operation, and higher torque density for demanding applications.

Harmonic Drives Structure

Main Components

Harmonic drives use three main parts to achieve precise motion: the circular spline, the flex spline, and the wave generator. Each part has a special job in the system.| Component | Function |

| Circular Spline | Acts as the rigid outer ring with internal teeth. |

| Flex Spline | Serves as a thin, flexible gear that fits inside the circular spline. |

| Wave Generator | Deforms the flex spline to engage the teeth and create motion. |

Flex Spline

The flex spline is a thin, cup-shaped gear made to bend without breaking. It fits tightly inside the circular spline. The wave generator pushes against the flex spline, causing it to flex and engage the teeth of the circular spline. This action creates the unique motion of harmonic drives.Studies have found that the flex spline faces the most stress at the top of its teeth. Over time, wear between the flex spline and the circular spline can affect how accurately the system moves. Engineers use special materials and shapes to make the flex spline last longer and work better. They also study how the flex spline handles repeated bending and twisting to make sure it stays strong.

Wave Generator

The wave generator is an oval-shaped part with a bearing. It fits inside the flex spline and forces it to take on an oval shape. As the wave generator turns, it moves the flex spline’s teeth in and out of contact with the circular spline.Tests using laser sensors show that the wave generator causes both regular and random bending in the flex spline. The amount of bending changes with speed. The flexible bearing inside the wave generator helps control these movements, making the system more reliable.

Operation

Deformation Mechanism

Harmonic drives use a special way to create motion. The wave generator sits inside the flex spline and pushes it into an oval shape. As the wave generator turns, it moves the flex spline’s teeth in and out of contact with the circular spline. This action causes the flex spline to deform elastically. The flex spline bends but does not break. The circular spline has two more teeth than the flex spline. Because of this, each turn of the wave generator makes the flex spline move forward by two teeth. This small movement creates a large reduction in speed and a big increase in torque.The deformation mechanism works because the flex spline is stiff when twisted but can bend easily in and out. The teeth on the flex spline and circular spline stay in contact along the major axis of the oval. This contact happens over many teeth at once, not just one or two. The S-tooth profile increases the area where the teeth touch. This spreads out the force and helps the gear last longer.

| Parameter Name | Description | Measurement Type / Units |

| Load at elliptical gear | Loads used for efficiency and temperature models | Numerical array (N·m) |

| Efficiency matrix | Gear efficiency at different loads and temperatures | Numerical matrix (ratio) |

| Follower angular velocity threshold | Speed below which efficiency smoothing is applied | Scalar (rad/s) |

| Friction model | Type of friction model used | Categorical |

| Sun-planet and ring-planet efficiencies | Torque transfer efficiency between gear pairs | Vector (ratio) |

| Temperature | Temperatures for efficiency lookup | Vector (K) |

| Sun-planet efficiency | Output-to-input power ratios | Vector (ratio) |

| Input shaft torque at no load | Power loss when input shaft turns with no output torque | Scalar (N·m) |

| Nominal output torque | Torque value for normal efficiency | Scalar (N·m) |

| Efficiency at nominal output torque | Efficiency at normal torque | Scalar (0 < η ≤ 1) |

| Follower power threshold | Power below which efficiency smoothing is applied | Scalar (W) |

| Sun-carrier and planet-carrier power thresholds | Minimum power for full efficiency factors | Vector (W) |

| Viscous friction coefficients | Friction at base and follower shafts | Two-element vector (N·m/(rad/s)) |

Tip: The unique deformation mechanism in harmonic drives allows for high reduction ratios and smooth, quiet operation.

Torque and Backlash

Harmonic drives can transmit a lot of torque for their size. The special design lets many teeth engage at once, which spreads out the force and makes the gear strong. The flex spline’s stiffness helps it handle high loads without twisting too much. The S-tooth profile also helps by making the teeth stronger and increasing the area where they touch.Tests show that harmonic drives have almost no backlash. Engineers measure backlash by locking the wave generator and circular spline, then applying torque to the flex spline in both directions. They measure how much the flex spline twists before the teeth move. The results show a very small amount of lost motion, called torsional backlash. Finite element analysis supports these results. Choosing the right size for the flex spline and circular spline is important for keeping backlash low.

- The S-tooth profile helps distribute the load and makes the gear last longer.

- Harmonic drives show excellent positioning accuracy and repeatability.

- The design keeps friction low and maintains minimal backlash during the gear’s life.

- High rigidity and peak torque capacity make these gears good for demanding jobs.

Rotational accuracy shows how closely the output matches the input.

Torque transmission capacity tells how much force the gear can handle.

Efficiency measures how much input power turns into useful output.

Lifespan shows how long the gear will last.

Quietness means the gear does not make much noise.

Minimal backlash means the gear moves smoothly and stops exactly where needed.

These features make harmonic drives a top choice for robots, airplanes, medical machines, and other equipment that need precise, reliable motion.

Advantages

Precision

Harmonic drives deliver outstanding precision in motion control. Engineers have studied how small errors in the system affect performance. They break down these errors into two main parts: nonuniform motion and lag. This analysis shows a beat frequency pattern, which means the errors repeat in a predictable way. Researchers also look at how mistakes in making or assembling the parts, such as tooth shape or wave generator alignment, can change the drive’s accuracy. By testing these drives with special equipment, they confirm that the error models match real-world results. Even with some small imperfections, harmonic drives can achieve high precision positioning. This makes them a top choice for tasks that need exact movement.Note: Careful design and testing help harmonic drives reach the high accuracy needed for robotics, aerospace, and medical devices.

Torque-to-Size

Harmonic drives stand out for their ability to deliver high torque in a small package. Multiple teeth engage at once, which lets the drive handle heavy loads without getting bigger or heavier. The table below shows key performance statistics that highlight this advantage:| Performance Metric | Description / Value |

| Torque Capacity | High output torque equal to drives twice the size and three times the weight |

| Reduction Ratio (Single Stage) | Ranges from 50:1 to 320:1 |

| Backlash | Zero backlash due to natural gear preload and radial tooth movement |

| Positional Accuracy | Within one arc minute; repeatability within a few seconds |

| Torsional Stiffness | High, improved by "S" tooth profile for greater precision and higher servo gains |

| Efficiency | Up to 90% operating efficiency based on shaft-to-shaft tests |

| Size and Weight Advantage | Compact size with concentric input/output shafts allowing reduced packaging space |

- Multiple tooth engagement enables high torque capacity and high torsional rigidity.

- Speed reduction ratios range from 80:1 to 260:1.

- Output torque ranges from 22.5 lb-ft (smallest model) up to 3,500 lb-ft (largest model).

- In aerospace , a cargo winch using a harmonic drive weighs only 290 pounds but matches the capacity of conventional units twice its size and weight.

Compactness

Designers often choose harmonic drives for their compact and lightweight structure. The unique arrangement of the flex spline, circular spline, and wave generator allows the drive to fit into tight spaces. The input and output shafts line up, which saves even more room. This compactness helps in building smaller robots, lighter aircraft parts, and portable medical devices. The drive’s small size does not limit its power or accuracy. Instead, it lets engineers create advanced machines that are both efficient and easy to handle.Tip: Compact harmonic drives help reduce the overall size and weight of machines, making them easier to transport and maintain.

Reliability

Reliability is a key advantage of harmonic drives. Engineers test these drives by applying torque loads and watching for signs of wear or failure. In one set of tests, 3D printed drives with thin flex spline walls failed quickly, showing the importance of strong materials and good design. By making the flex spline thicker and improving the bearing contact, the drives lasted longer and moved more smoothly. Changing the wave generator to use a single bearing also helped. These tests show that careful design choices can solve common problems and make the drive more reliable. When built with the right materials and tested under real conditions, harmonic drives offer smooth, dependable operation for many years.- Regular improvements in design and materials increase the lifespan of these drives.

- Smooth operation means less noise and less wear over time.

- Engineers can trust harmonic drives for critical tasks in robots, planes, and medical tools.

Applications

Robotics

Robotics uses special gear systems to achieve precise and smooth movements. These systems help robots perform tasks that require high accuracy and strength. Many robots in factories, hospitals, and warehouses rely on these gears for their joints and arms. The gears allow robots to lift heavy objects, move with great control, and repeat actions many times without losing accuracy.High torque output with a small size helps robots work in tight spaces.

Low or zero backlash ensures robots stop and start exactly where needed.

High repeatability allows robots to perform the same task over and over.

Compact design makes robots lighter and easier to build.

Robots in industrial automation, healthcare, and collaborative settings benefit from these features. For example, surgical robots use these gears to make tiny, careful movements during operations. Collaborative robots, or cobots, work safely alongside people because of their precise control.

Aerospace

Aerospace engineers need gear systems that work well in extreme conditions. These gears must handle high torque, stay accurate, and fit into small spaces. Space missions, satellites, and aircraft use these gears for tasks like moving solar panels, controlling flight surfaces, and guiding missiles.NASA first used these gears in the Apollo 15 lunar rover in 1971. Since then, they have appeared in space telescopes and Mars rovers. The gears offer zero backlash and high reduction ratios, which are important for space equipment. They also use strong materials that can survive cold and work without oil. These features help spacecraft move smoothly and stay reliable during long missions.

Medical

Medical devices need gears that provide exact movements in small spaces. Robotic surgery systems, such as the da Vinci Surgical System, use these gears to help doctors perform delicate procedures. The gears allow for steady, controlled movements, which can improve patient outcomes.Medical imaging equipment also uses these gears to position cameras and tools with great accuracy. The compact size and high precision make them ideal for devices that must fit inside the human body or work in crowded operating rooms.

| Accuracy Class | Accuracy Range (arc-minutes) | Suitable Applications | Industry Relevance and Growth Trends |

| Standard | 0.01 - 0.1 | Applications not requiring high precision | General industrial use |

| High | 0.001 - 0.01 | Moderate precision needs | Used in robotics, medical devices, aerospace components |

| Ultra-High | < 0.001 | Highest precision applications | Fastest growing segment; critical for aerospace, surgical robots |

Selection Criteria

Choosing the right drive for a project depends on several important factors. Engineers look at torque, speed, environment, precision, cost, and lifespan before making a decision. Each factor affects how well the drive will work in its intended application.Torque and Speed

Torque and speed are two of the most important criteria. Drives must deliver enough torque to move loads without slipping or stalling. They also need to match the speed requirements of the system. The table below compares key performance aspects:| Performance Aspect | Details |

| Torque Capacity | High output torque, often matching drives twice the size and three times the weight. |

| Speed Reduction Ratio | Single-stage ratios from 50:1 to 320:1 for significant speed reduction. |

| Precision & Repeatability | Positional accuracy within one arc minute; repeatability within a few arc seconds. |

| Efficiency | Up to 90% in shaft-to-shaft tests. |

Environment

The working environment affects drive selection. Some drives must operate in clean rooms, while others face dust, moisture, or extreme temperatures. Materials and seals protect the drive from damage. For example, space missions need drives that work in a vacuum and survive large temperature swings. Medical devices require clean, sterile operation.Tip: Always check the drive’s material and sealing options for the intended environment.

Precision Needs

Precision matters most in robotics, medical, and aerospace fields. Drives must meet strict standards for accuracy and repeatability. The table below shows typical values:| Precision Standard | Description | Typical Values |

| Transmission Accuracy | Angular error per rotation | 1", 3", 5" (arc sec) |

| Repeatable Positioning | Consistency after many moves | 5" to 10" (arc sec) |

| Reduction Ratio | Output speed to input speed | 30 to 160 |

Cost and Lifespan

Cost and lifespan play a big role in the final choice. Drives with fewer parts and efficient power transfer last longer and need less maintenance. Although the initial price may be higher, these drives save money over time by reducing downtime and repair costs. Their compact design also saves space and energy.- High precision reduces errors and costly rework.

- Efficient design lowers maintenance needs.

- Customization options help match the drive to specific tasks.

Maintenance

Proper maintenance helps gear systems last longer and work better. Regular care keeps machines running smoothly and prevents costly breakdowns. The following best practices focus on inspection, cleaning, and lubrication.Inspection

Technicians should check gear systems often. They look for signs of wear, cracks, or loose parts. A good inspection schedule might include:- Checking for unusual noises or vibrations during operation

- Looking at the flex spline and circular spline for damage

- Making sure the wave generator moves smoothly

- Tightening bolts and fasteners if needed

A simple inspection checklist helps workers remember each step. They should record any issues and fix them right away.

Cleaning

Clean gear systems work better and last longer. Dust, dirt, and old grease can cause problems. Workers should:- Wipe off dust and debris with a soft, dry cloth.

- Use a gentle brush for hard-to-reach areas.

- Avoid water or harsh chemicals that can damage parts.

- Remove old lubricant before adding new grease.

Lubrication

Lubrication reduces friction and wear. It also helps the system run quietly. Workers should use the right type of grease or oil for the gear. They should:- Apply lubricant at regular intervals, based on the manufacturer's advice

- Use only the recommended amount—too much or too little can cause problems

- Check for leaks or dried-out grease during each inspection

| Maintenance Task | Frequency | Notes |

| Inspection | Monthly/Quarterly | Look for wear and damage |

| Cleaning | Monthly | Remove dust and old grease |

| Lubrication | As recommended | Use correct lubricant type |

Harmonic Drives vs. Other Gears

Traditional Gears

Traditional gears, such as spur and helical gears, use rigid teeth that mesh together. These gears often appear in machines like cars, clocks, and industrial equipment. They provide reliable power transfer and can handle high speeds. However, traditional gears usually have some backlash. Backlash is the small gap between gear teeth that can cause lost motion. This gap can lower precision in tasks that need exact movement.Traditional gears also need more space because of their design. They often require extra parts to reduce backlash or increase torque. Engineers sometimes add springs or special shapes to improve performance, but these changes can make the system more complex. Maintenance for traditional gears can be higher because of wear on the teeth.

| Feature | Traditional Gears | Harmonic Drives |

| Backlash | Present | Nearly zero |

| Precision | Moderate | Very high |

| Size | Larger | Compact |

| Torque Density | Lower | Higher |

Cycloidal Gears

Cycloidal gears use rolling pins and discs to transfer motion. These gears can handle high torque and resist shock loads. Many industrial robots and conveyors use cycloidal gears because they are strong and durable. Cycloidal gears have less backlash than traditional gears, but they still do not match the precision of harmonic drives.Cycloidal gears are usually larger and heavier. Their design uses more moving parts, which can increase noise and vibration. Engineers choose cycloidal gears for heavy-duty jobs, but they may not fit in small spaces. Harmonic drives, with their flexible spline and wave generator, provide smoother motion and higher accuracy.

- Cycloidal gears: Good for heavy loads and tough environments.

- Harmonic drives: Better for precise, quiet, and compact systems.

Future Prospects

Materials

Engineers continue to search for better materials to improve gear systems. They now use advanced alloys and composites to make parts lighter and stronger. Many researchers focus on the flex spline because it faces the most stress. New materials help this part last longer and resist bending or breaking. Some companies use special processing techniques to shape these materials with high precision. These changes help gear systems work better in tough environments like space or clean rooms.- New gear shapes improve how gears share force and move together.

- High-performance materials extend the life of important parts.

- Better processing equipment increases accuracy and stability.

Performance

Gear systems now reach higher levels of accuracy and strength. Engineers design new gear shapes to reduce errors and handle more weight. They use advanced machines to cut and finish each part with great care. This attention to detail means the gears move smoothly and quietly. Many companies test their products in real-world settings to make sure they meet strict standards. As a result, gear systems now work better in robots, airplanes, and medical tools.Note: Improved performance helps machines run longer and need less repair.

New Applications

Many industries now use these gear systems in new ways. Aerospace companies install them in satellites and space probes. Medical device makers use them in surgical robots and imaging machines. The semiconductor industry relies on them for precise movement in chip-making tools. The rise of humanoid robots, like those made by Tesla, pushes companies to develop even better gear systems. Mass production and new research drive more innovation every year.- Aerospace , medical, and semiconductor fields demand higher performance.

- Humanoid robots need precise and reliable motion control.

- Market growth encourages more research and development.

- Robotics, aerospace, and medical equipment all benefit from accurate positioning and smooth, reliable movement.

- Industry trends like smart manufacturing and miniaturization increase demand for these drives.

-

New materials and improved manufacturing methods expand their use in advanced automation.

These features make them essential in many modern machines and future projects.

FAQ

What makes harmonic drives different from regular gears?

Harmonic drives use a flexible spline and a wave generator. This design gives them almost zero backlash and high precision. Regular gears often have more backlash and less accuracy.How long do harmonic drives usually last?

Most harmonic drives last many years with proper care. Regular inspection, cleaning, and correct lubrication help extend their lifespan. Strong materials and good design also improve durability.Can harmonic drives work in extreme environments?

Yes. Engineers use special materials and seals so harmonic drives can work in space, clean rooms, or places with high or low temperatures. These drives often appear in aerospace and medical equipment.Do harmonic drives need a lot of maintenance?

Harmonic drives need less maintenance than many other gear systems. Simple tasks like checking for wear, cleaning, and adding lubricant keep them running smoothly. Most users find them reliable and easy to care for.

×

×